Spring Linseed Agronomy

Anywhere in the UK.

Spring Linseed can be grown on all soils.

Row widths of 10 – 30 cm show little difference in yields.

Seed rates are dependent on the thousand grain weight (TGW). Through our extensive research we have changed are seed rates from 650 seeds/m2 to 800 seeds/m2 with Nulin (VT50) having the higher seed rate of 1000 seeds/m2 to ensure a good plant population. This equates to 60-80kg/ha or 24-32kg/acre however this will depend on variety and the thousand grain weight (TGW).

Growth regulation on Spring Linseed is often not needed, however in the case of an early sown crop on fertile sorry, an application of a Metconazole based product can be used.

The Flax Flea Beetle is the main pest for Spring Linseed (different from the Cabbage Stem Flea Beetle found in Oilseed Rape). The beetle will eat away at the first true leaves on the cotyledon.

The threshold for chemical control is 10-15 beetles/m2.

More information on the flax flea beetle can be found in our bulletins.

To control the Flax Flea Beetle you can use Hallmark which is approved on an EAMU at a rate of 75ml/ha or CleanCrop Corser at 150ml/ha. Both are effective against the Flax Flea Beetle and both are approved or use on Spring Linseed.

See the EAMU box for product links.

Due to the short growing season of Spring Linseed thanks to our early maturing varieties, leaf/tissue diseases are rare so fungicides are not used pre-flowering. In forward crops, a late onset of Septoria linicola can sometimes occur. This can be dealt with a robust application of a Difenconazole product. Post flowering in wet seasons, Botrytis can develop on the seed bols so Tebuconazole is recommended as a preventative option. Please see EAMU section for approved products.

Trace Elements should be applied to rectify known field deficiencies. Best practise usually see’s these applied with post-emergence herbicides to reduce sensitivity of the Linseed.

Crop heigh ranges between variety and growing season, but can be between 30cm – 60cm.

Spring Linseed varieties have been screened for important characteristics – earliness to harvest, standing ability, yield and Omega 3 content. This ensures you have the best varieties for your farm whilst growing the quality the market needs. Chasing an extra few percent of yield at the expense of earliness or standing power is false economy.

The “EasyCut” varities Marquise and Empress have established themselves as favourites with customers looking for easy harvesting, high yielding characteristics.

The high Omega-3 varieties Omegalin and Nulin (VT50) have found favour with those seeking additional premiums for oil quality.

A well-managed Linseed crop should be ready to harvest after completing the Wheat harvest – typically late August/early September. Linseed should flow well through the combine even with green stems.

Always desiccate Linseed for an early and easy harvest. Glyphosate are approved on Linseed as a desiccant. See the Eamu box below for product links.

Desiccation of Linseed is based on the colour of seed and overall look of the crop. The lower leaves will have fallen off and the stem will still be green. Seeds will be full sized, plump and ivory (for both brown and yellow seeded varieties). Pods are likely to be yellowy-lime green in colour.

Harvest from 14 days after spraying although this will be dependant on timing and weather post-desiccation. Most combines handle linseed well. However, there are reports of linseed straw wrapping around the rear rotor of CLAAS Lexion combines due to the rubber paddles attached to it which snag the straw. This affects 2013 and older combines and a standard set of Linseed rotors are fitted to all newer models of the CLAAS Lexion combines.

Contract dependent. Requirements differ based on end use.

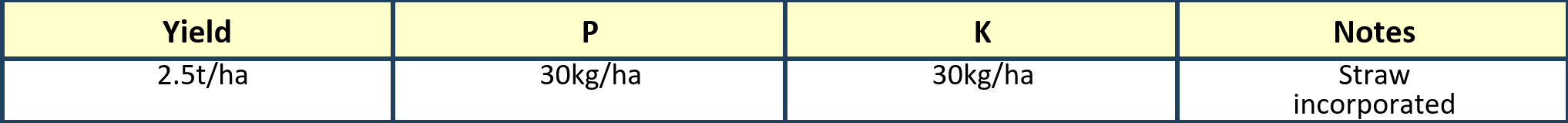

Premium Crops average yields for our Spring Linseed varieties is 1.7 – 2.3t/ha.

Linseed straw can be disposed of either by chopping or burning.

Linseed will typically be harvested at 8.5% to 12% moisture, with the market standard being 9%. Linseed can be dried in any system that will handle OSR, with similar temperature settings. Care needs to be taken when drying linseed on-floor or in a bin system. Linseed, being a flat seed has a very high resistance to airflow, so the drying front can stall after about a metre or so, resulting in a hard, wet layer. To avoid this, do not dry linseed on-floor above a metre in depth, or in a bin system you will need to rotate with an empty bin. For a Protimeter conversion chart, click here.

Fully Approved products for Linseed

Links are provided below to the Authorisation document for each of the products.

This list is not exhaustive - for a complete list of products approved for Spring Linseed please visit the HSE database.

All products below were Authorised at the time they were added to this list, while Premium Crops do regularly check the validity of the products and update the list accordingly, it remains the Grower's responsibility to make sure that the Authorisation remains valid at the time any product is used.

Ally SX FMC Agro Limited

Afrisect 500 EC (cypermethrin) Agriphar S.A.

Dow Shield 400 Corteva Agriscience UK Limited

Eagle Interfarm UK Limited

Eagle Sumitomo Chemical (UK) Plc

Eagle Bayer CropScience Limited

Fusilade Forte (fluazifop-P-butyl) Nufarm UK Ltd

Fusilade Max (fluazifop-P-butyl) NuFarm UK Ltd MAPP NO. 19013

Jubilee SX FMC Agro Limited

Laya (metsulfuron-methyl) Life Scientific Limited

Roundup Biactive Monsanto (UK) Limited

Roundup Biactive GL Monsanto (UK) Limited

Roundup Energy Monsanto (UK) Limited

Roundup Flex Monsanto (UK) Limited

Roundup Klik Monsanto (UK) Limited

Roundup Metro XL Monsanto (UK) Limited

Roundup POWERMAX Monsanto (UK) Limited

Permasect 500 EC Arysta LifeScience Benelux SPRL

Supasect 500 EC (cypermethrin) Agriphar S.A.

EAMUs for Spring Linseed

Detailed below are the products listed by the Health and Safety Executive as having an Extension of Authorisation for a Minor Use of a Plant Protection Product. (EAMU)

It is essential that anyone who needs to use a product in accordance with an Extension of Authorisation must read the text of the Extension of Authorisation before commencing any spraying operation. Links are provided below to the Authorisation document for each of the products.

All products below were Authorised at the time they were added to this list, while Premium Crops do regularly check the validity of the products and update the list accordingly, it remains the Grower's responsibility to make sure that the Authorisation remains valid at the time any product is used.

Ambarac (metconazole) Life Scientific Limited

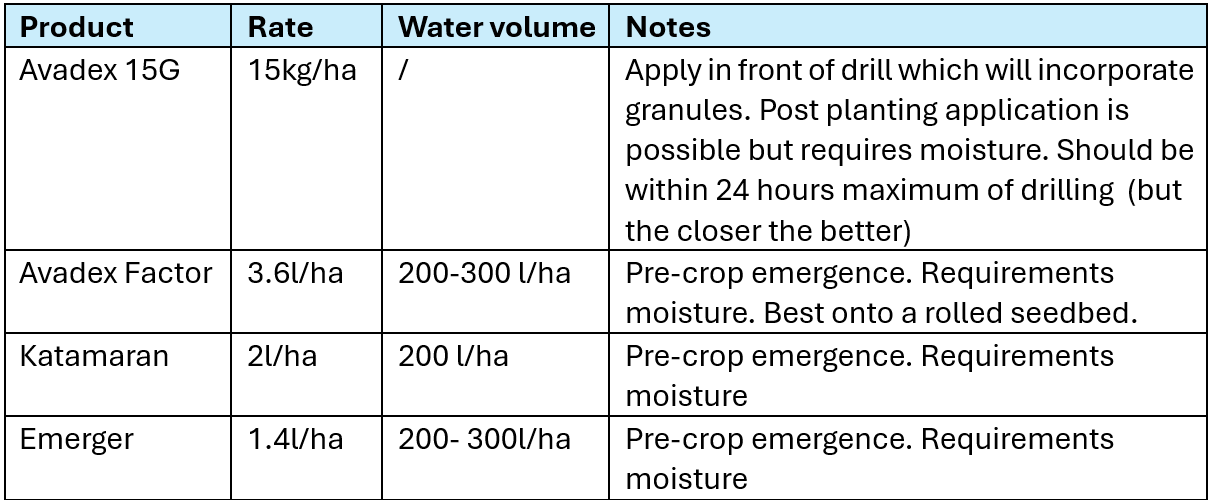

Avadex Excel 15G (tri-allate) Gowan Comercio Internacional e Servicos Limitada

Avadex Factor (tri-allate) Gowan Crop Protection Ltd

Balistik (clethodim) Arysta LifeScience Great Britain Ltd

Basilico (mesotrione) Life Scientific MAPP 18028 final use by 28/02/2025

Basilico (mesotrione) Life Scientific MAPP 19927

Butisan S (metazachlor) BASF Plc

Calisto (Mesotrione) Syngenta Crop Protection UK Ltd MAPP 19756

Caramba (metconazole) BASF Plc

Centurion Max (clethodim) Interfarm UK Ltd

Clayton Comply Clayton Plant Protection Limited

CleanCrop Corsair (lambda-cyhalothrin) Agrii, a trading name of Masstock Arable (UK) Ltd

Contest (alphacypermethrin) BASF plc

Defy Syngenta UK Limited under MAPP Number 16202

Difcor 250EC (difenoconazole) Q-CHEM nv

Difenostar (difenoconazole) Life Scientific Limited

Emerger (aclonifen) Bayer CropScience Limited

Filan (Boscid) BASF plalc - see also; Filan (MAPP 11449)

Hallmark with Zeon Technology (lambda-cyhalothrin) Syngenta UK Ltd

Juventus (metconazole) BASF plc

Katamaran (metazachlor) BASF plc

Klartan (tau-fluvalinate) Adama Agricultural Solutions UK Ltd

Lambdastar (l lambda-cyhalothrin) Life Scientific Limited

Makila 500 SC (metazachlor) Novastar Link Limited

Markate 50 (lambda-cyhalothrin) Agrovista UK Ltd

Mavrik (tau-fluvalinate) Adama Agricultural Solutions UK Ltd

Maxim 480FS (fludioxonil) Syngenta UK Limited

Metaz 500 (metazachlor) Novastar Link Limited

Metazacare (metazachlor) AGROCARE Chemichals Kft

Metfin 90 (metconazole) Clayton Plant Protection Limited

Rapsan Solo (metazachlor) Belchim Crop Protection Limited

Rapsan Solo (metazachlor) Certis Belchim B.V.

Proline 275 (prothioconazole) Bayer CropScience Ltd

Quidam UPL Europe Ltd

Select Prime (clethodim) Arysta LifeScience SAS

Sultan 50 SC (metazachlor) Adama Agricultural Solutions UK Ltd

Sunorg Pro (metconazole) BASF plc

Toprex (difenoconazole and paclobutrazol) Syngenta UK Ltd

The above is a list of all products listed on the HSE website and as such does not represent Premium Crops' endorsement or recommendation for use.

Please note an EAMU does not ensure a product is safe to use.

Emergency Authorisation

Emergency Approvals (EA) have been granted for desiccant Spotlight Plus to use on linseed seed production crops only until the 30th September 2024.

Any usage must comply with the stewardship rules, viewable here.

A record of use form must be completed and sent to uk.stewardship@fmc.com by 31st December 2024.